Custom Insert molding Services:

Precision Integration for Metal and Plastic Components

In search of a good quality and powerful precision insert molding solution? You are on a good article. Our expertise lies in plastic insert molding and metal insert molding, which are both strong and efficient, and offer a smooth transition. With more than 20 years of experience as insert molding manufacturers located in Dongguan, China, our professionals are found busy in serving our clients in the whole of North America and Europe with prompt delivery, quality consistency, and technical excellence. We can accommodate the requirements of your project, whether you are an engineer, product designer or procurement expert.

Happy customers

5-star reviews

Quality That Lasts

Why Choose Us for Insert Molding?

Being a known insert molding manufacturer across the globe, we merge the strength of innovation, automation, and people-centred values.

Experience of 10s of years

Our experienced group of people offers more than 10,000+ completed insert molding projects to our global customers.

Full In-House Capability

All of it (from mold design to tooling, molding, and post-processing) is done in our very complex facility.

Quick Turnaround

Prototype and production quantities, short lead times, and operation lines of 24/7 molds.

Design Engineering Support

We provide DFM reports, material suggestions and assessment of performance in order to get your design to production.

Flexible production quantities

Whether it is a 100-piece customized order or 1 million parts, we can quickly adjust with no effect on quality.

STR Global Reach

We have a global delivery and we can provide technical communication in English, French and German in order to co-ordinate with ease.

Stepwise Perfection

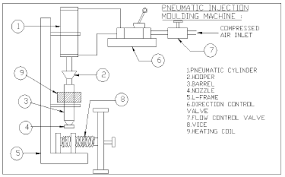

Insert molding Procedure

Step-by-Step

Insert Preparation

Inserts (metal and non-metal) are washed, pre-heated or prepared and placed correctly in the mold. This is either achieved manually or through automated robotic systems to achieve greater accuracy.

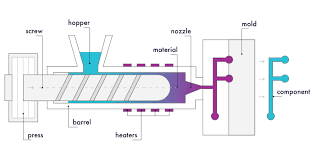

Plastic Injection

Thermoplastic resin is forced into the mold under high pressure and controlled temperatures; the plastic melt flows around the insert, producing a single and integrated component.

Cooling & Ejection

After the part cools, it is ejected and checked over to check integrity, alignment and strength of bond. Step-by-step process flow chart/cut-away drawing of plastic injected around insert (as image suggestion).

Insert Preparation

Inserts (metal and non-metal) are washed, pre-heated or prepared and placed correctly in the mold. This is either achieved manually or through automated robotic systems to achieve greater accuracy.

Plastic Injection

Thermoplastic resin is forced into the mold under high pressure and controlled temperatures; the plastic melt flows around the insert, producing a single and integrated component.

Cooling & Ejection

After the part cools, it is ejected and checked over to check integrity, alignment and strength of bond. Step-by-step process flow chart/cut-away drawing of plastic injected around insert (as image suggestion).

Insertable Materials

Our service provides a variety of insert materials in terms of functional use and application:

Metals: Stainless steel, brass, copper, aluminium and zinc alloy.

Non-Metals: Ceramics, magnets, wire mesh, pre-molded plastic parts and even circuit boards.

Popular Resins in Plastic

- ABS (Acrylonitrile Butadiene Styrene) – Is good in structural cases.

- Nylon (PA) – Strong, heat-resistant.

- Polycarbonate (PC) -prefix: These materials are apparent and are impact-resistant.

- Polypropylene (PP) -This is flexible and lightweight.

- PEEK PEEK is incredible in high-performance applications.

- TPE/TPU- Soft enough to provide grips or seals.

Dimensional Tolerances

Precision tolerance: less than or equal to 0.05mm, depending on the geometry.

Insert positioning: reliable repeatability through automated or jig-assisted placement. Insert positioning: Automated or jig-assisted insert placement. Insert positioning: Reliable repeatability through automated or jig-assisted insert placement.

Such close tolerances are needed in applications where alignment is critical to performance or safety, e.g. in injection molding metal inserts.

Services

What Is Insert Molding?

Insert molding is a particular type of injection molding, in which a pre-made (typically metallic or other) component is inserted into a mold and molten plastic is injected around it. The outcome stands as an all-in-one integrative component, which has the characteristics of strength of an insert coupled with plastic form and flexibility. This allows the manufacturing of high-performance parts to be done with fewer post-molding steps and in a more efficient manner. Insert molding Applications are:

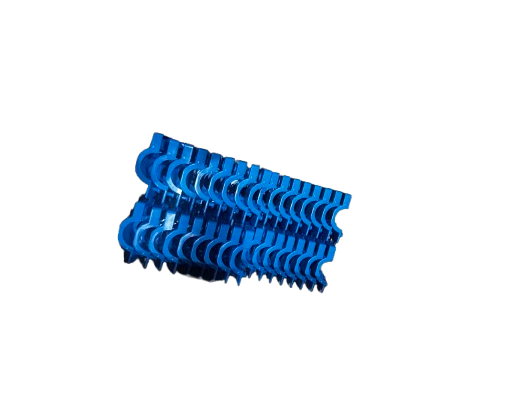

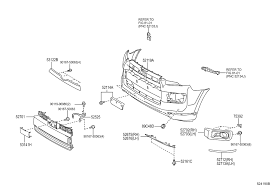

Automotive Components

Insert molding used in automotive manufacturing to create strong, precise, and durable parts that withstand harsh environments. Ideal for high-performance assemblies in vehicles. Includes: Sensor housings, screw mounts, clips, fasteners.

Medical-Grade Solutions

Specialized insert molding for sterile and accurate medical components, ensuring safety, precision, and performance in life-critical applications. Suitable for mass production of delicate instruments. Includes: Needles, surgical tools, diagnostic devices, needle hubs.

Consumer Electronics

Insert molding helps create sleek, space-efficient parts essential in modern electronics. Ideal for precision fitting, durability, and compact design in daily-use devices. Includes: Plugs, switches, wearables, phone connectors.

Industrial Equipment

Industrial applications benefit from insert-molded parts that are strong, custom-fit, and durable under pressure. Designed for long-term performance in demanding work conditions. Includes: Custom brackets, housings, cable interfaces.

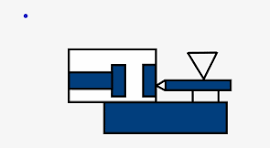

Molding and Injection Vector Diagrams

Comparison

Insert Molding vs Over Molding

Though in both processes, insert molding and overmolding, multiple materials are used, these processes and outcomes are quite different:

Insert molding is the preferred solution when you need strong bonds between plastic and metal, or where threaded inserts for plastic molding are required. Our capability has been refined to ensure quality, consistency and scalability between batches, from prototype to high-volume production.

Insert Molding

- Plastic is injected over a pre-positioned insert.

- Materials Used: Metal, ceramic, pre-molded plastic

- Best For: Strength, mechanical bonding, conductivity

- Examples: Electrical connectors, surgical components

Overmolding

- A second material is molded over a base component.

- Materials Used: Rubber, TPE, soft plastics

- Best For: Grip, aesthetics, comfort, sealing

- Examples: Tool handles, wearable devices

Industries We Support

The Industries That We Serve

We favour various markets in which insert molding injection is a very essential aspect in product development. We also make sure that every project adheres to well-defined industry-specific criteria, particularly in regulation-sensitive industries such as automotive and medical devices.

Strategic collaboration

We provide solution that fully matches your company or product. If you work with your own end customers, we can also support you with co-branded marketing activities.

Completely customized

We design your environment completely customized, implement it and take care of the management. We work together with your internal department or responsible.

Access to all experts

Your key users will have direct access to our senior engineers and consultants, enabling us to deliver a service at the highest level.

We Support

- Automotive

- Sensor mounts

- The fuel system parts

- Dashboard mounting pins

- Medical Devices

- Mobile diagnostic shingles

- Dental instruments

- The injection system deals with

- Consumer Electronics

- Portable smart gadgets

- Bluetooth accessories

- Switches and buttons

- Industrial & Electrical

- Cable entrance plugs

- Electronic control boxes

- Power connectors and plugs

Advantages

Benefits Of Insert Molding

Insert molding is an effective and cost-efficient means of producing a finished project since it is directly set in a plastic component. Insert molding is not only a manufacturing process but also a solution to a design. The reason why engineers and designers love it is this:

Increased Durability

It has increased durability because of the rigid metal cores, enhancing structural strength and resistance to material wear.

Shorter Assembly Time

Consolidates several components into a single component, thus avoiding the use of screws or glue.

Creative Product Development

Allows the development of small designs and creative products.

Lower manufacturing costs

Reduces the amount of labour, inventory of parts, and post-processing.

Lightweight Efficiency

Perfect to use in mobile or aerospace parts, which require lightweight parts to remain tough.

Electrical/Conductive Applications

Excellent in situations where terminals, shielding material or sensor packages are to be integrated.

FAQs

Frequently Asked Questions

Unsure about something? Check out our FAQs to learn more about working with independent contractors, our approach, and how we ensure quality and satisfaction.

What is the distinction between insert molding and conventional mechanical assembly?

Insert molding bond parts together as they are being injected and there is no need to add fastening or bonding after molding. It makes the parts more streamlined and stronger.

Is it possible to insert molding electrical parts?

Yes. We do a lot of jobs in the form of molding conductive metal inserts in order to make composite electronic housings and connector components, as well as switchgear components.

How would I place a quote request?

You can easily upload your drawings (STEP, IGES, STL, DWG or PDF) via our web or email us. Our engineers will review your file and give you a complete quote in 24-48 hours.

Contact Us

Get A Free Quote In Just 12 Hour's

In need of professional insert molding design? Our precision-engineered injection molding with metal inserts? Or ready to customise your production? We got you. We do not only manufacture parts, but we also engineer long-term solutions that not only enhance your production, advance your product, and decrease your schedule.

victorabc@gmail.com

Phone

+112 233 445

Office

123 Sample St, Sydney NSW 2000 AU